Textile Machinery

Textile machinery encompasses a wide range of equipment used in the manufacturing, processing, and finishing of textiles. Below are details of different types of textile machinery:

1. Clothing Industry Equipment

Includes machines used in the garment and apparel manufacturing industry.

-

Cutting Machines – Automated and manual fabric cutters.

-

Sewing Machines – Industrial and home sewing machines.

-

Embroidery Machines – Used for decorative stitching on fabrics.

-

Ironing & Pressing Machines – Steam press, fusing press, and garment finishing machines.

2. Coating Machinery

Used for applying coatings to textiles for protection, waterproofing, or special finishes.

-

Lamination Machines – Apply protective film layers.

-

Coating Units – For chemical or polymer coatings.

-

Spray Coating Systems – Even distribution of coatings.

3. Dyeing, Printing, and Finishing Machines

Equipment used to color, print, and apply final treatments to textiles.

-

Dyeing Machines – Jet dyeing, beam dyeing, pad dyeing.

-

Printing Machines – Rotary screen, digital, heat transfer printing.

-

Finishing Machines – Softening, stiffening, waterproofing, and other enhancements.

4. Knitting Machinery

Machines used for producing knitted fabrics.

-

Circular Knitting Machines – Used for seamless garments, t-shirts, and hosiery.

-

Flat Knitting Machines – For sweaters, scarves, and fashion wear.

-

Warp Knitting Machines – Produces fabrics like lace and mesh.

5. Laundry Machinery

Used in industrial textile washing and finishing.

-

Washing Machines – Industrial washing of fabrics.

-

Drying Machines – Large-scale tumble dryers.

-

Ironing and Pressing Machines – Automated fabric pressing.

6. Non-Woven Machinery

For manufacturing non-woven fabrics used in medical, hygiene, and industrial applications.

-

Needle Punching Machines – Produces felt and synthetic leather.

-

Spunbond Machines – Creates non-woven polypropylene fabrics.

-

Meltblown Machines – Produces filter media and hygiene products.

7. Preparatory Process Machinery

Equipment used in fiber processing before spinning and weaving.

-

Carding Machines – Aligns fibers before spinning.

-

Combing Machines – Removes short fibers and impurities.

-

Blow Room Machines – Cleans raw cotton or wool.

8. Sewing and Garment Machinery

Includes specialized machines for garment production.

-

Overlock Machines – Stitching and edge finishing.

-

Flatlock Machines – Seam joining for activewear.

-

Buttonhole & Button Sewing Machines – Automated attachment of buttons.

9. Spinning Machinery

Machines for yarn production from fibers.

-

Ring Spinning Machines – Produces high-quality yarns.

-

Open-End (Rotor) Spinning Machines – High-speed yarn production.

-

Compact Spinning Machines – Reduces hairiness in yarn.

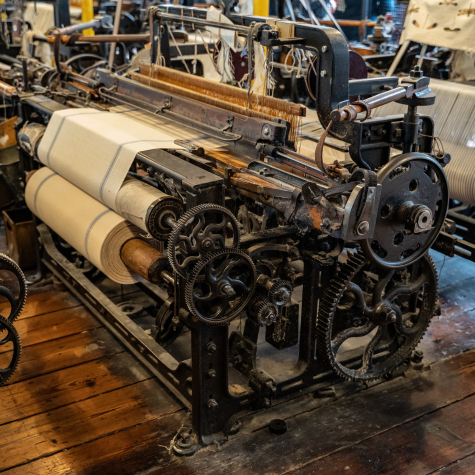

10. Textile Machinery Parts

Spare parts and components for textile machines.

-

Spindles and Bobbins – Used in spinning and weaving.

-

Needles and Hooks – Used in knitting and embroidery.

-

Belts, Bearings, and Gears – Essential machine components.

11. Weaving Machinery

Machines used for interlacing threads to create fabric.

-

Looms (Air-Jet, Water-Jet, Rapier, Shuttle Looms) – Different weaving techniques.

-

Jacquard Machines – Used for intricate woven patterns.

-

Warping and Sizing Machines – Preparatory processes for weaving.

12. Other Textile Machinery

Additional specialized machines used in textile production.

-

Textile Recycling Machines – Converts waste fabric into reusable fiber.

-

Laser Cutting Machines – Precision cutting of fabric.

-

Ultrasonic Welding Machines – For seamless fabric bonding.

customerservice@thehapston.com

sales@thehapston.com

Call Us

+91 75033 45444